English

العربية

Deutsch

English

Español

Français

Italiano

한국어

日本語

Português

Русский

Tiếng Việt

Türkçe

DIN Rail

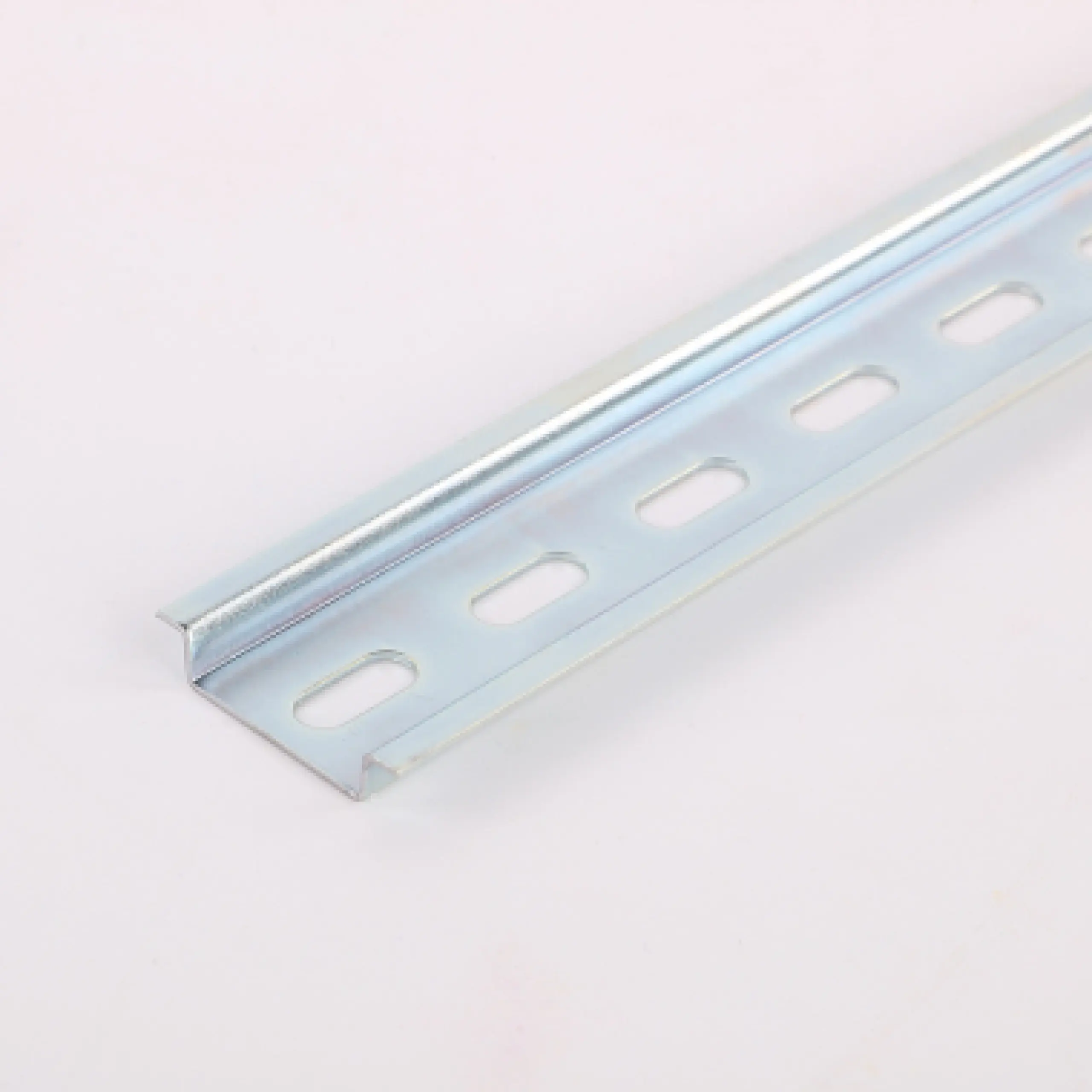

35x7.5mm DIN Rail

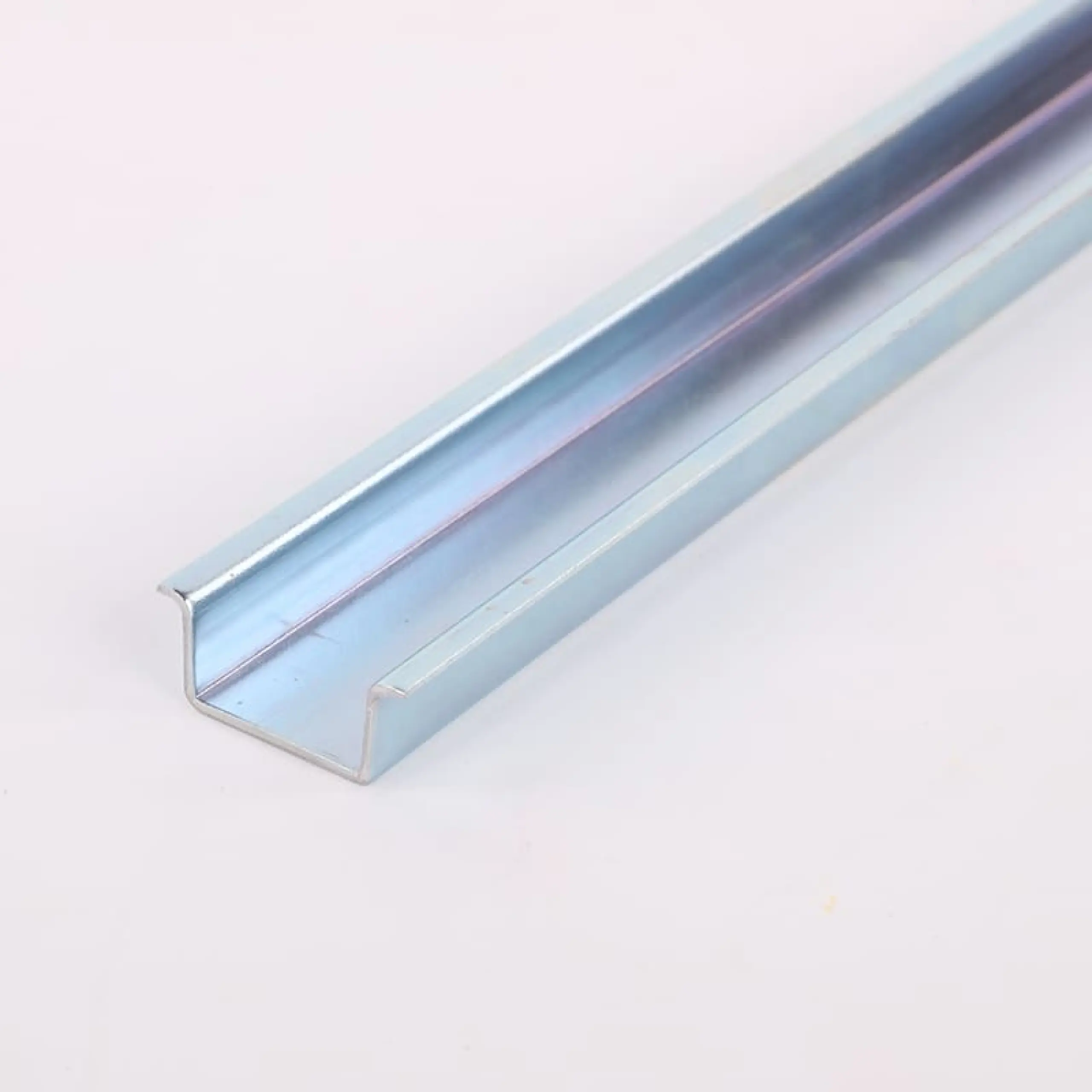

35x15mm DIN Rail

32x15mm DIN Rail

15x5.5mm DIN Rail

Top Hat DIN Rail

G Type DIN Rail

Mini DIN Rail

Aluminum DIN Rail

Steel DIN Rail

Stainless Steel DIN Rail

DIN Rail Clip

Stainless Steel DIN Rail Mounting Bracket Clip DR Z6036E15

Steel DIN Rail Adapter Clip DR Z4934E15

Aluminum DIN Rail Clamp Clip DR Z4740L23

DIN Rail Cutter

DIN Rail Channel Cutter DR Q1L

Top Hat DIN Rail Cutter DR Q1LA

DIN Rail Cutter Tool DR Q1LB

Din Rail Cutting Tool DR Q1H

DIN Rail Cutting Machine DR Q4LHGM

1F, Bld 27, No.536 Shunfeng Road, Linping District, Hangzhou, China

Copyright ©Hangzhou T&G Technology Co., Ltd. All Rights Reserved.

Sitemap|Privacy Policy| Powered by:yofishseo.com